You are readingULPA Filter Media: The Ultimate Clean Air Solution

The air that you breathe or even the %age of clean air would have been derived out from ULPA filter media. The modern-day scenario, where the levels of pollution are increasing and howl for breathable air has reached an unprecedented level due to ongoing pandemic threat. This is where ULPA filter media comes as a powerful technology solution for fighting air-borne contaminants. ULPA, abbreviation for Ultra-Low Particulate Air is the much advance technology than its predecessor HEPA.

Learn About ULPA Filter Media & Comparison With HEPA Filters

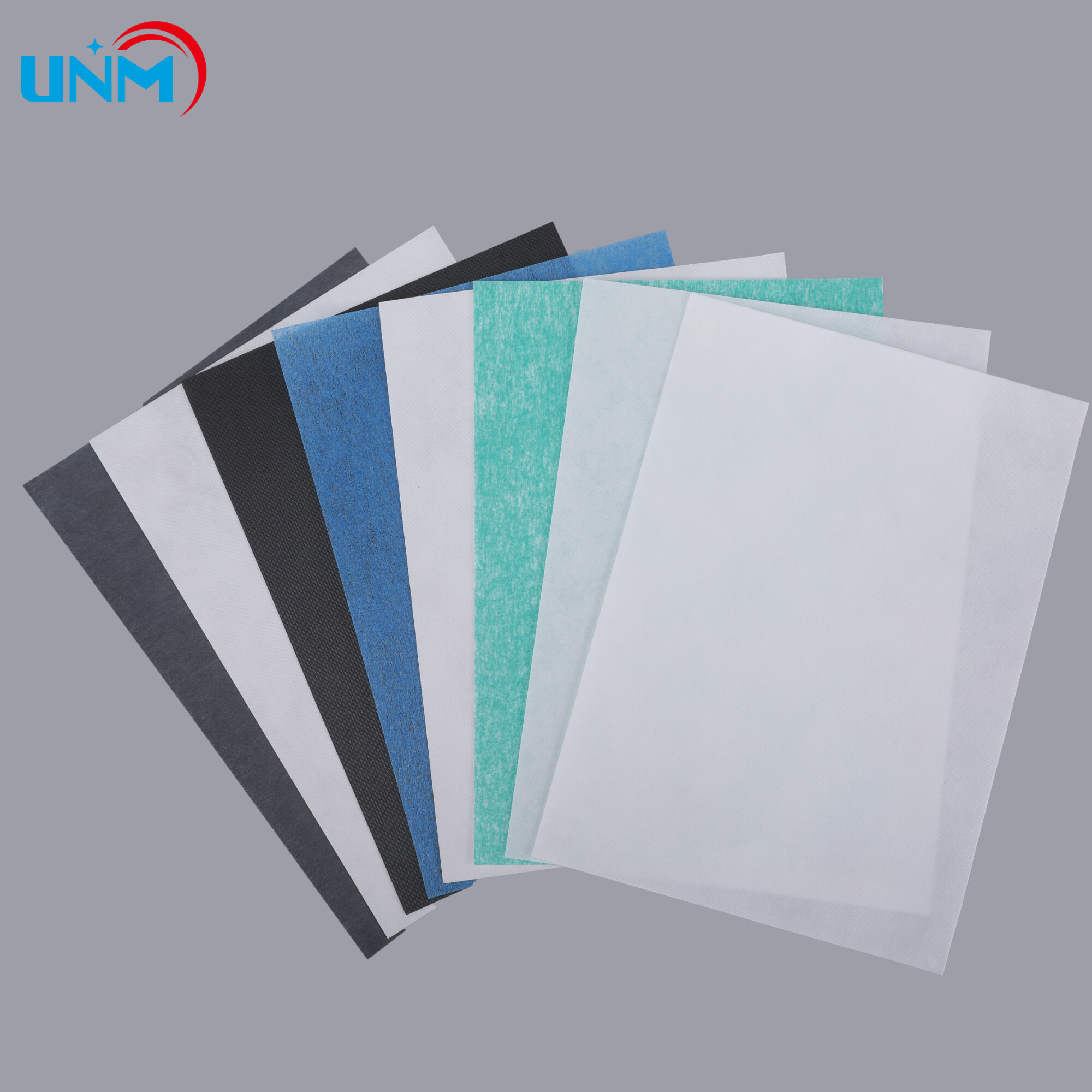

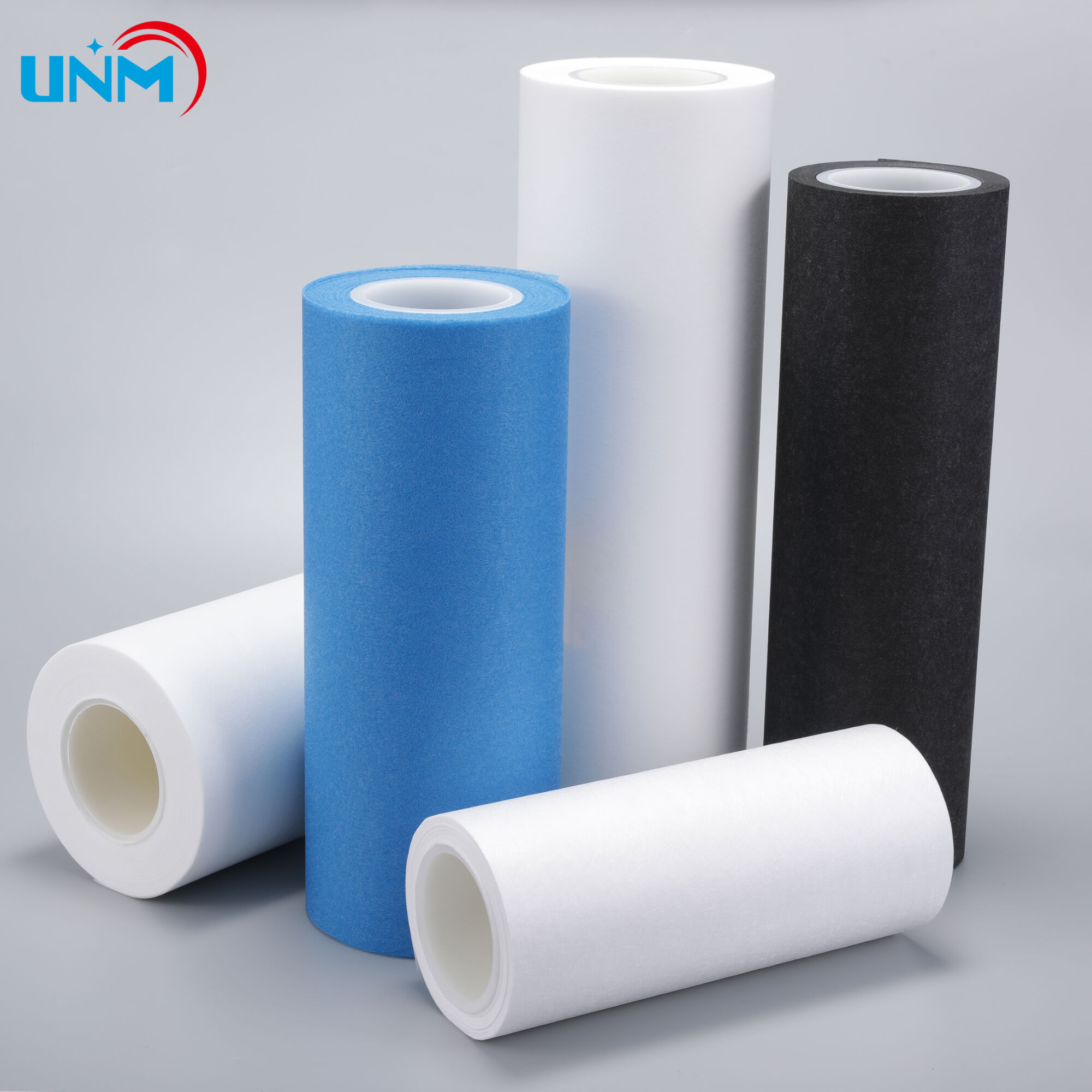

ULPA filter media is an advanced filtration technology used in a variety fields, including medical, pharmaceutical and electronics to create sterile air environments. Filter media: the filter is made up of millions and thousands of ultra-blue fibers, resulting in a high efficiency rate capture range (0.12 micron) at 99%. This means that ULPA filters are even more efficient than HEPA filters, which have a 99.97% efficiency in trapping particles as small at 0.3 microns

Broad.spectrum comparisonWith a history of more than 50 years, Camfil is one the top manufacturers in air filtration solutions for critical applications including cleanrooms.

Pall Corporation: With more than 75 years of experience, Pall is a leading global provider of filtration and separation products for high-purity air filters, including ULPA filters.

Donaldson Company: A well-known global provider of pioneering air filtration solutions, Donaldson Company provides a range of customised ULPA filters which purify the surrounding atmosphere in sensitive settings.

MANN+HUMMEL: MANN+HUMML offers more than 75 years of experience to manufacturers, specifically in the field of industrial air filtration where it celebrates a broad portfolio, including world-renowned ULPA filters with exceptional uptime performance.

IqAir: From Switzerland, IqAir have established themselves as the premium air purification system and their selection of ULPA filters are built for critical applications that require top of line air quality.

The cleanroom technology is employed in every domain where small particles can adversely affect the quality of the product like pharmaceuticals, biotechnology electronics and healthcare etc. ULPA filters are important components in cleanroom technology as they work nonstop to keep the air flowing and circulation of airborne particles int he room at a minimum. In cleanrooms, the air is constantly filtered and airflow keeps higher pressure compared to atmospheric one so no external contaminate gets sucked in. The ultra-fine fibers of ULPA filters play a critical role in removing contaminants up to virus size and beyond from the air, holding onto particles until they can be sterilized or removed by vacuum.

There are many benefits of using ULPA filter media for air purification, among them:

Ultra-efficient: Forget HEPA filters, and step into a higher tier of the clean air era with ULPA technology capturing 99.999% tiny particles from your environment making this an efficient filter market to offer today!

Decreased contamination: The use of ULPA filters diminishes airborne particulates in contexts where the degree of contaminant is essential such as cleanrooms for industries including biotechnology, pharmaceutical and electronics.

Improved Safety: The segregation of polluted air can maintain consistently high levels of safety in sensitive environments such as hospitals and labs.

Better Air Quality: ULPA filters help to improve indoor air quality and eliminate from the atmosphere pollutants, allergens, and harmful particles that are unhealthy for building occupants.

This battle between ULPA and HEPA filters finally draws a line when it comes to capturing ultra-fine particles where the cleaner, denser pack of ULPA works in favor. Even though HEPA filters are 99.97% efficient in capturing particles as small as 0.3 microns, ULPA filters can filter down to a level of.12 with affordingly better tests at an efficency of...

To Sum Up, ULPA Filter Media is an Air Filtration Technology that has gone through significant technological advancements over the past few years and growing across different industries worldwide. Its top-of-the-range air purification capabilities for ultra-fine particles means that it is the best choice in environments demanding maximum efficiency. This bodes well for the future, with major innovators in this industry like Camfil, Pall Corporation and Donaldson Company breaking ground into new realms with their air purification technologies.