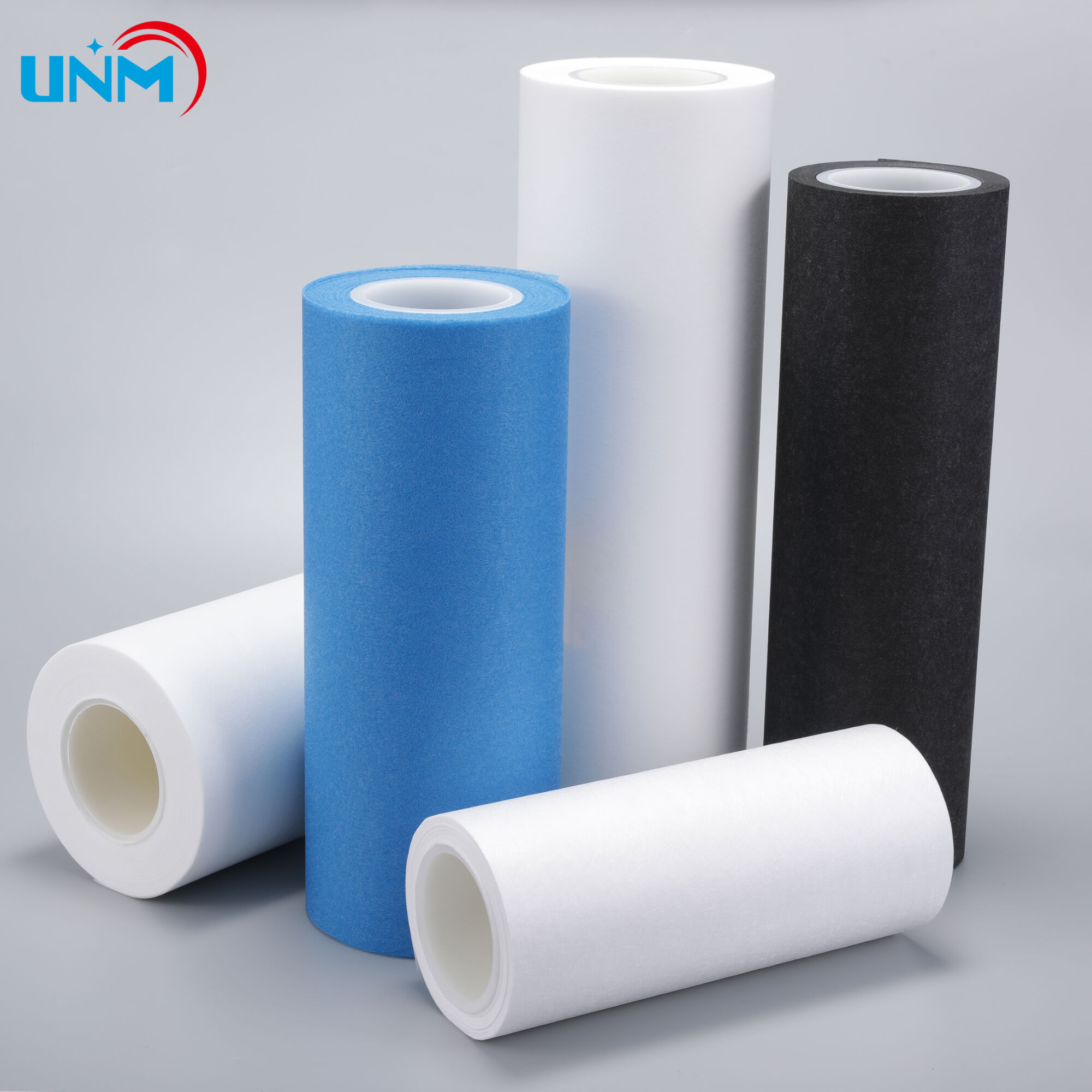

You must have wondered about Roll filter media and the cleaning up it does, right? If you said no, then not to worry - we're about to introduce this amazing filter right here. What Is Roll Filter MediaRoll filter media is a type of mesh that can be used to clean the air and water. This device, specialized in trapping particles and impurities that can be present due to user of the filtering medium is applied throughout a single sheet of filter material (filter media) so that the filtered material after passing through this will strive to become as clean as possible.

The Surprising Advantages of Roll Filter Media for Industrial Filtration Systems

Used to enhance production speeds, or as a standalone pre-filter medium ahead of larger filter media supplies; roll filtration material offers several advantages for industrial filtration systems. Now, let us go in detail of a few of the benefits.

Roll media are one of the most effective filtration medias to remove impurities from liquid systems (water, etc.) or gaseous streams. Behind the conditionsthese regulations are an important pre-requisite for faultless functioning of any goods handling plant or machinery, as without compliance with them contaminants can quickly make a piece of equipment non-functional.

Other than being affective, roll filter media is also highly efficient extracting large amounts of particles and contaminants in whatever substance you are filtering. It does not save time but over her long history has proven to be economically wasteful.

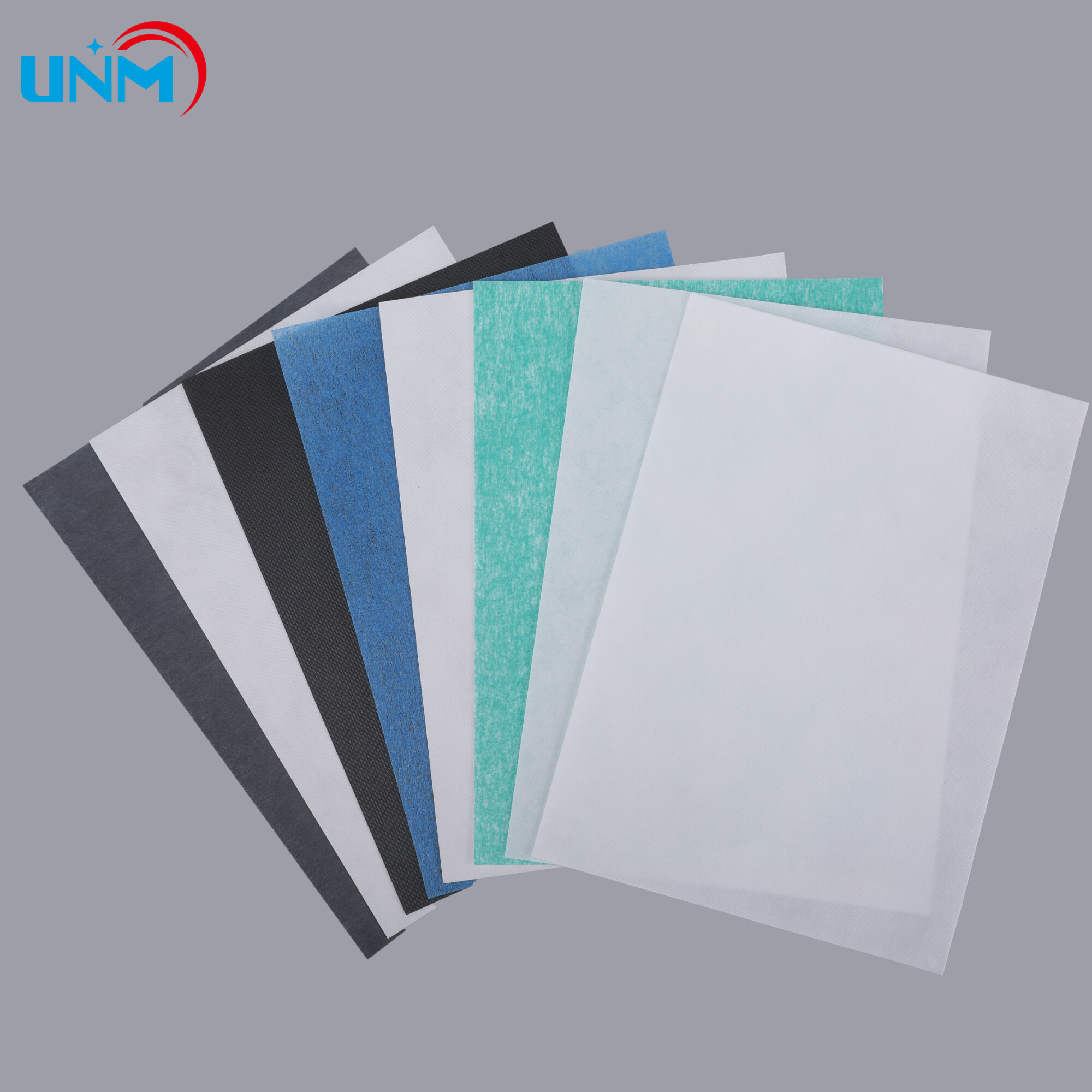

In addition to which, roll filter media is infinite-use-ability-there are many different styles that meet the several industrial filtration needs. Due to its malleability, it can work across various systems for different purposes.

There is much more to think about when you choose the right roll filter media for your filtration issue. Here are a few guidelines to follow and choose the best one for you:

Well, followed by sensible about the type of materials you're filtering. There are different types of roll filter media that target specific substances, so you need to select the one that suits your purpose.

Second; identify the size of unwanted particles or contaminations. The length and spin of roll filter media is so you can use one that works for your application, really the width/density.

Lastly, think about the flowrate at which product is being filtered. Roll filter media has the capability to flow a highly variable range of flows, so you must ensure that the type is appropriate for your system.

Roll filter media really is effective as a result of some scientific basics we know from physics. Here is a high level overview of this feature :

These materials have tiny pores on their surface which can effectively trap particulates and any other substance present in the fluid when filtered through it, but at a higher cost.

Pore size will dictate what particles can be mechanically filtered. If the holes are too large, particles smaller than intended can pass through, and if they're made too small, it will also prohibit passage of what is being filtered.

Pore size and fluid flow rate are the parameters on which performance of roll filter media is based. However after all these factors are added up, there will still be superior roll-filter media with different properties.

Best Practices for Roll Filter Media Installation and Maintenance The right kind of install & regular maintenance to ensure top performance from your systems Here are the steps:

Protective perforated rolls Filter media type (You can use the following rollers) Select the appropriate roll filtererenorsk heckliste

Adhere to manufacturer's instructions when installing roll Filter Medias for your machinery.

Maintain the cleanliness of the roll filter media, and clean it with water to ensure that its efficiency is kept.

OUR EXPERTISE IN ACTION The Environmental Advantages of Roll Filter Media from a High Performance Filtration System

The filter media of a roll not only can add method in which that may eliminate harmful particles through an additional product, but it's created for use across the long run. Let's explore why:

Eco-Friendly: Some roll filter media is made from recyclable and/or recycled plastic materials, which will provide an easy answer to your sustainability needs.

This high efficiency-the four-fold increase in material surface area per gram which is easy to convert into reduced demands for filters materials-is both cost grading as well much greener.

When roll filter media requires replacement, which is typically a small percentage of the filters, it can often be recycled or disposed properly.

Now that you know everything about media in roll filter, take a step ahead to use its benefits for various industrial filtration processes. Make good selections, follow instructions for installation and maintain. Happy filtering!

UNM is top provider service for every customer. We are able customize products roll filter media to requirements of customers' data use the best production solutions and packaging solutions to meet clients' diverse requirements for their products. Prior to product leaving factory, each roll of material is tested thoroughly only those that have met the requirements are permitted to leave the warehouse. are able to prepare the products according to manufacturing cycle of the client, making sure that the product is of high quality and delivered quickly.

Our company employs ISO9001 IATF16949 systems managing controlling every element of production process that includes PTFE materials to the management and production processes. The machine in operation all day long ensure the quality of the product across batches. information from each roll of material recorded in the system only after it has been checked. Only those products that meet production requirements will be allowed to be roll filter media from the warehouse. The factory is committed 6S system and strictly adheres to the production standards as well as production safety. Every single one of the UNM employees strive to provide outstanding service and to create every item perfection.

UNM is expert manufacturer of EPTFE Microporous Membranes. With a particular focus membrane that are used for fluid air filtration garment fabrics, hydrogen proton exchanges base membranes etc. We able to choose most suitable samples according customer requirements and offer free samples them to test their data. We able to provide free samples if there isn't appropriate product. Early on, accept small samples from customers. If any of samples that are not in line with roll filter media, we adjust the product based on data comparison and analysis. Up until the time of production products are satisfactory to customers. will reply every consulting within shortest possible time and will provide appropriate samples for testing.

have an in-house R D lab, which aims continuously improve innovate update and iterate our products, replace imported ones, and fill the gaps certain areas that are domestically produced. Our proton exchange base, high-efficiency filters and microporous Bubble Point membrane have all received positive reviews from the market in country. We have worked with Zhejiang University as well as other universities to jointly develop new PTFE membranes and roll filter media projects. We have also obtained several patents for inventions and utility model patents.